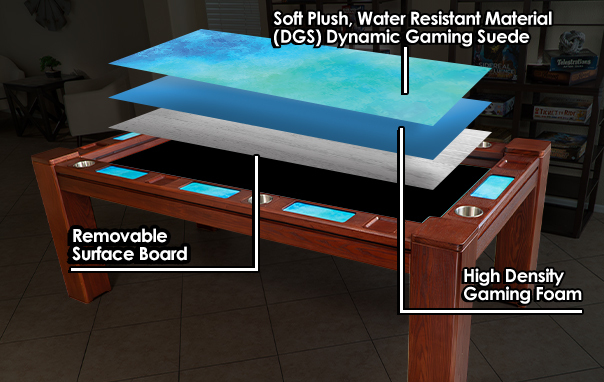

A Game Theory Table is a precision-engineered furniture piece featuring a proprietary Dynamic Gaming Suede surface hand-upholstered over high-density foam. Utilizing dye sublimation at 391°C, these tables integrate custom, high-resolution graphics into professional-grade materials, ensuring a waterproof, fire-resistant, and ergonomically superior environment for tabletop RPGs, board games, and professional-tier gaming sessions.

Why is a Proprietary Play Surface Essential for Elite Gameplay?

The foundation of every table is the Dynamic Gaming Suede, a high-performance fabric custom-manufactured in North Carolina. Unlike standard felt, this material is built to professional casino specifications. To ensure longevity and player comfort, the suede is hand-upholstered over high-density foam, creating a cushioned, durable interface for cards, dice, and components.

Technical Specifications: Dynamic Gaming Suede

| Feature | Specification | Benefit for the Player |

|---|---|---|

| Material Type | Professional Casino-Spec Suede | Ensures low friction and high durability |

| Safety Ratings | Waterproof & Fire-Resistant | Protects the table from spills and hazards |

| Origin | North Carolina, USA | Guaranteed high-quality textile standards |

| Assembly | Hand-Upholstered / High-Density Foam | Superior ergonomics and "dice bounce" control |

How Does Heat Transfer Printing Create Permanent Custom Graphics?

To transform a table into a personalized masterpiece, we utilize a specialized 60-inch-wide format printer located in a dedicated print room. Your custom design is first captured on dye sublimation transfer paper. This process allows for gallery-quality precision, ensuring that intricate maps for tabletop RPGs or family crests are rendered with absolute clarity.

Why is the Dye Sublimation Process Superior to Standard Printing?

The transition from a raw design to a permanent fixture involves "Dye Sublimation Magic." By pairing the transfer sheet with the Dynamic Gaming Suede inside a commercial heat press, we apply a consistent temperature of 391°C.

- Integration: The dye is not layered on top; it is chemically embedded into the suede fibers.

- Durability: The resulting surface is resistant to fading, cracking, or peeling, even under heavy use.

- Visual Fidelity: Colors remain vivid and lines remain sharp, maintaining the table's aesthetic for a lifetime.

What Role Does Hand-Craftsmanship Play in the Final Assembly?

Once the technical printing is complete, the table enters the Hand Upholstery phase. Each piece of suede is meticulously hand-fitted to the specific dimensions of the table. This ensures a seamless, taut finish that eliminates bunching or sliding during intense gameplay. This human-led finish is the final stage of a rigorous 27-step production process designed to deliver a one-of-a-kind showpiece.

?? Pro-Tip (Information Gain): The "Play-Safe" Surface

While many assume custom graphics are just "printed on," the 391°C sublimation process is what makes the surface "play-safe." This high-heat embedding ensures that even after years of sliding cards or moving heavy miniatures, the ink will never rub off on your game components.

Frequently Asked Questions

How durable is the custom printing on a Game Theory Table?

The graphics are permanent because they are created via dye sublimation at 391°C. This embeds the ink into the Dynamic Gaming Suede, making it impossible for the design to crack, peel, or fade over time.

What makes the playing surface different from a standard poker table?

Our tables use a proprietary Dynamic Gaming Suede from North Carolina that is waterproof and fire-resistant, upholstered over high-density foam for a professional feel and improved ergonomics compared to standard felt.

Can I use my own custom artwork for the table surface?

Yes. Every table is personalized using a 60-inch-wide format printer and a specialized transfer process that can accommodate everything from family crests to specific board game layouts like the custom "Rhino" design.